Double Layer Forming Fabric For Fine Paper Making

Customized Solutions for Your Paper Mill: Our paper machine forming fabric is available in various specifications, allowing you to choose the perfect fit for your unique production needs and enhance your operational capabilities.

Description

Reviews

Description

Double layer forming fabric usually means that the weft yarn has a double-layer structure. Compared with single layer forming fabric, double layer warp and weft have higher density, strong stability, and less stretchable.

For double layer forming fabric, in the weaving process, the diameters and material of sheet-side and machine-side wefts can be selected independently, enabling improvements in wire mark, two-sidedness, flatness, and fabric life.

Due to the special structure of the double-layer fabric, it has a large three-dimensional space, and the flat space is almost zero, so the double-layer fabric also provides excellent drainage performance. Drainage force does not directly affect the paper layer, which helps improve retention and prevents lint.

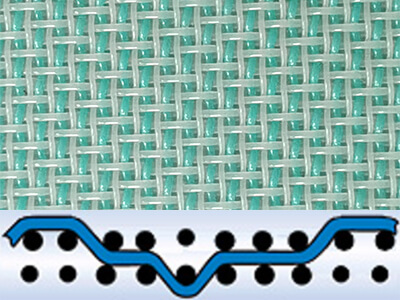

7-shed Double Layer Forming Fabric

The fabric has excellent surface properties to provide good fabric surface smoothness. It is suitable for paper with wire mark difficulties.

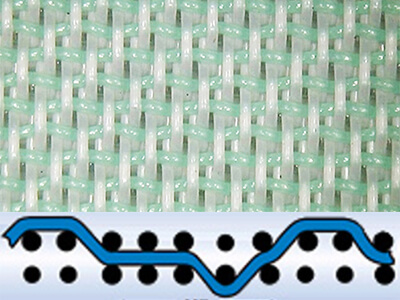

8-shed Double Layer Forming Fabric

The 8-shed double-layer forming fabric includes one set of longitudinal fiber heddles and two sets of transverse fiber heads, which allows fine fibers to be retained on the top layer, and thicker fibers are used at the bottom to help obtain better sheet forming characteristics. The fabric provides excellent drainage and abrasion resistance properties.

Feature

● Improved formation and retention.

● Improved fabric life.

● Enhanced dimensional stability and stretching resistance.

Application

Double layer forming fabric is suitable for producing quality paper which includes printing paper, wrapping paper, board grade, onion-skin paper, newsprint. It is suitable for medium and high-speed paper making machines.

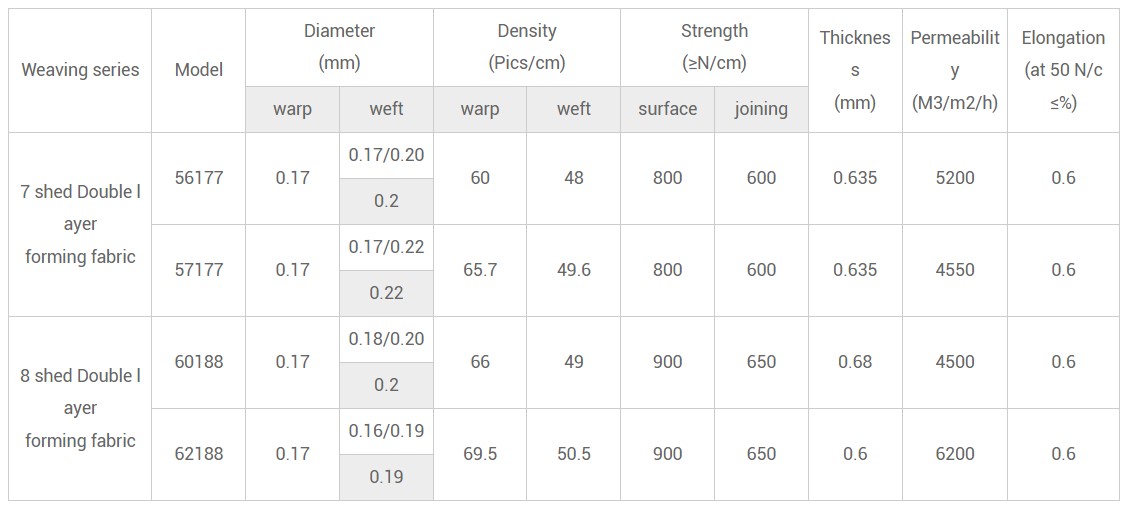

Specifications