Polyester Linear Screen Mesh Belt For Mining

Improve your filtration system’s longevity by choosing our premium filter belts. Built with the best materials and innovative technology, our belts ensure reliable, high-efficiency filtration and a perfect fit for your equipment. Bring more value to your operation with our trusted filter belt solutions.

Description

Reviews

Description

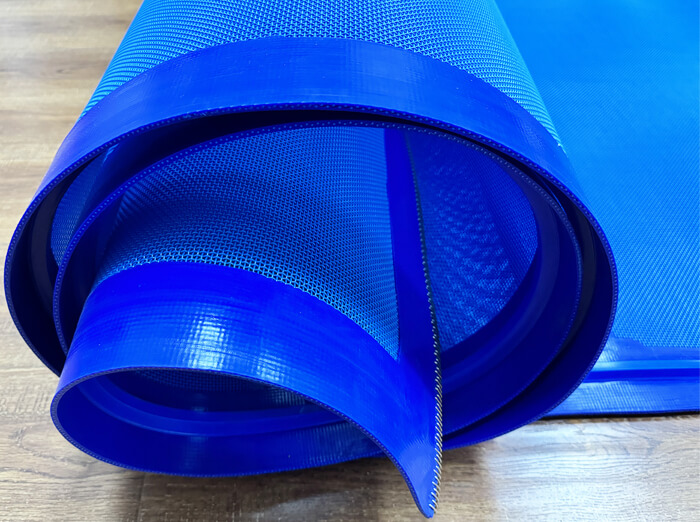

Polyester plain weave mesh fabrics are also called linear screen cloth, polyester mesh conveyor belts, and polyester monofilament process conveyor belting.

The weaving pattern is 2-shed and 3-shed and is available in various meshes, caliper, GSM and air permeability for different applications. Polyester monofilament process conveyor belting is available in a wide variety of yarn thicknesses and apertures.

The fabrics are widely used in various industries as dryer fabrics, conveyor belts, filter cloths and food & vegetables drying mesh belts.

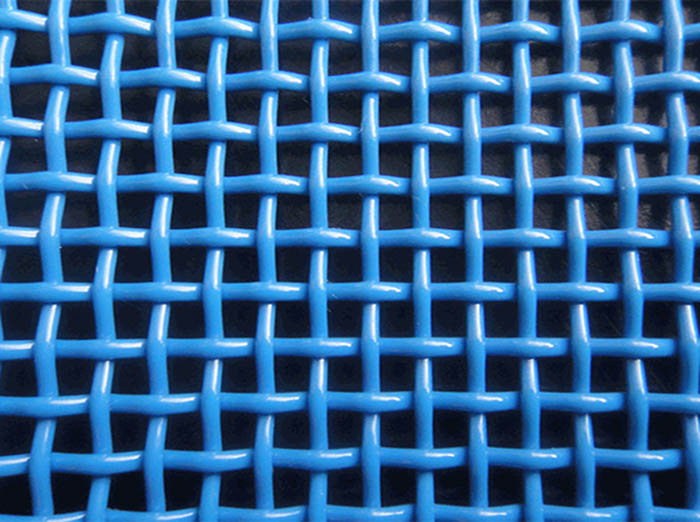

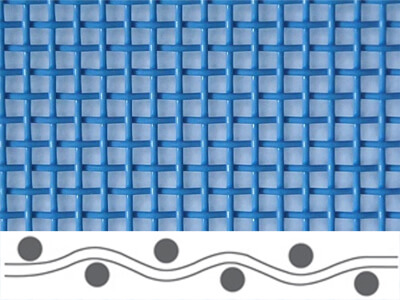

2-Shed Polyester Linear Screen

Filter fabrics with the 2-shed plain weave have high weave stability and predefined uniform size of apertures, so they can also be used to sort particles according to their size on linear screen separators.

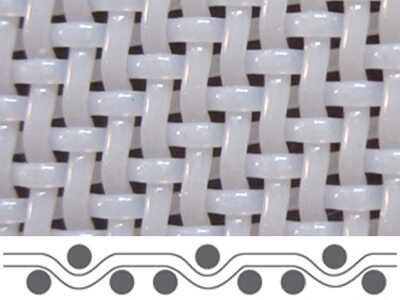

3-Shed Polyester Linear Screen

Filter fabrics with the three-shaft twill weave have a very high dewatering ability and a higher wear resistance than fabrics with the plain weave.

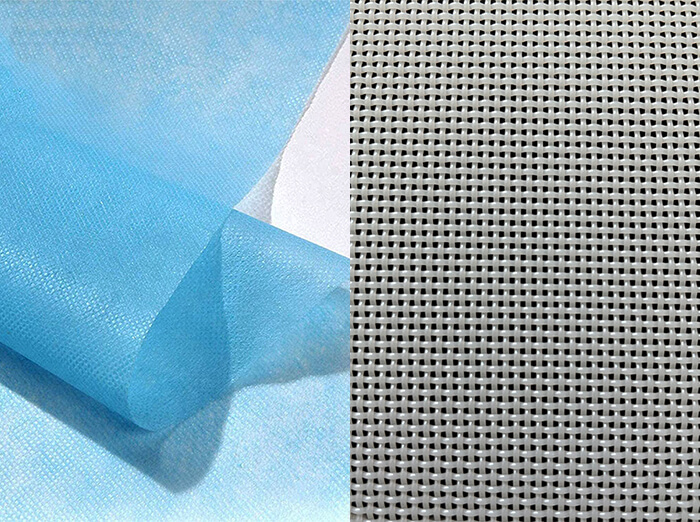

Reinforcement Polyester Dewatering Mesh Belt

These Dewatering Mesh Belts feature lateral and end reinforcements made exclusively from TPU or PVC belt material, ensuring compliance with food safety regulations.

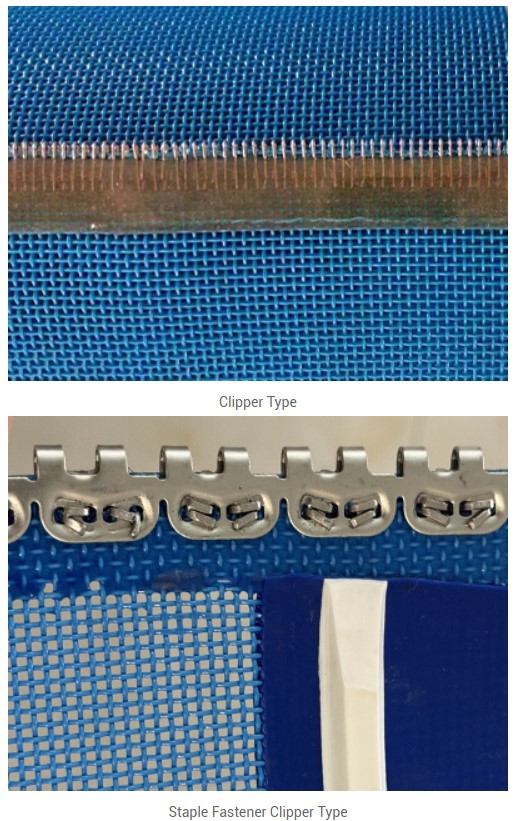

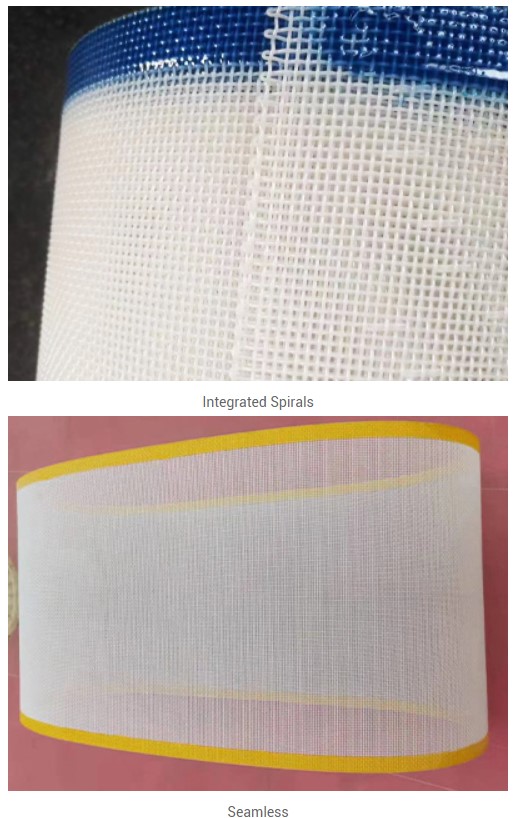

The jointing mechanism of the Polyester Mesh belts

The jointing mechanism of the polyester mesh conveyor belts can be manufactured in a number of ways ranging from metallic clipper types, integrated spirals to seamless.

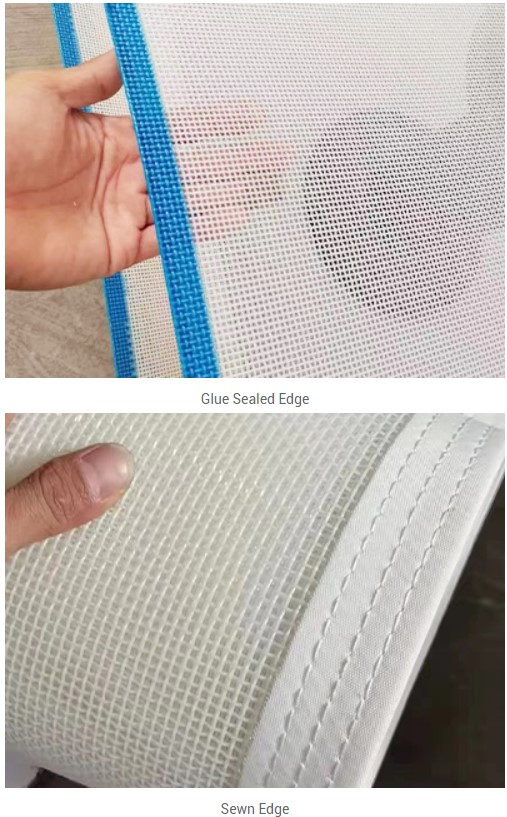

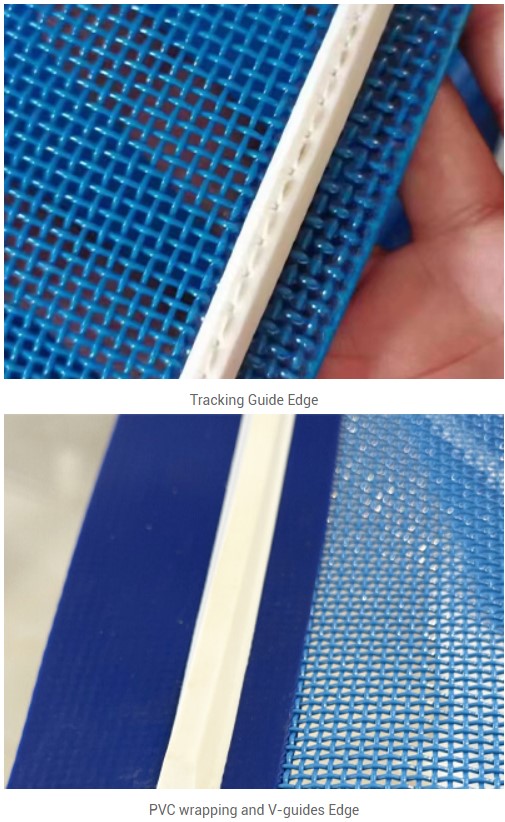

The edges of the Polyester Mesh Belts

The edges of the polyester mesh conveyor belts can be reinforced with special materials that make them resistant to fraying and abrasion by impregnation, encapsulation, or welding.

Polyester Mesh Belt is mainly used for the following processes:

● Filtration

● Separation

● Drain

● Drying

● Dewatering

Feature

● The nature of polyester mesh belt is that it offers a very durable long-lasting media for extended life.

● Strong polyester fibers provide excellent stability and good wear resistance.

● Offer a variety of joints including endless joint.

● Food approval: US FDA approval.

● Working temperature: -75°C to +150°C.

Application

● Pulp board making.

● Wood industry: Dryer belts of woodchips, particle boards, MDF/HDF, etc.

● Nonwoven cloth industry

● Food drying.

● Material screening and separation.

● Environment protection: sludge dewatering in belt press filters

● The pre-cleaning process before fruit and vegetable processing.

● Glass fiber mat production line

|

Polyester Linear Screen Mesh Belts for Washing |

Polyester Linear Screen Mesh Belts for Nonwoven |

Specification

|

Model |

Wire diameter (mm) |

Density (wire/centimeter) |

Strength |

weight (kg/m2) |

Thickness |

Mesh Radial/latitude (mm) |

Aperture Radial/latitude (mm) |

permeability (m3/m2/h) |

CFM/127Pa |

open aven |

|||

|

warp |

weft |

warp |

weft |

surface |

joint |

||||||||

|

021002 blue |

1 |

1 |

2.85 |

2.65 |

1600 |

650 |

0.6 |

1.85 |

7.10/6.73 |

2.50/2.77 |

32000 |

2000 |

52.55 |

|

031002 blue/white |

1 |

1 |

3.2 |

3.25 |

1600 |

650 |

0.8 |

1.86 |

8.10/8.20 |

2.12/2.07 |

25600 |

1600 |

45.9 |

|

03902 |

0.9 |

0.9 |

3.9 |

3.65 |

1600 |

650 |

0.55 |

1.7 |

9.60/9.30 |

1.66/1.83 |

20000 |

1250 |

46.58 |

|

04902 |

0.9 |

0.9 |

4.65 |

4.7 |

1600 |

650 |

0.95 |

1.66 |

44542 |

1.25/1.22 |

17600 |

1170 |

33.55 |

|

04602 |

0.5 |

0.6 |

4.4 |

5.2 |

1600 |

650 |

0.58 |

1.23 |

12/13.2 |

1.72/1.32 |

19000 |

1187 |

53.32 |

|

05602 |

0.6 |

0.6 |

5.9 |

5.6 |

1600 |

650 |

0.62 |

1.1 |

14.98/14.2 |

1.09/1.18 |

18000 |

1125 |

42.89 |

|

05802 |

0.8 |

0.8 |

5.1 |

5.3 |

1600 |

650 |

0.89 |

1.48 |

13/13.5 |

1.16/1.08 |

15840 |

990 |

34.09 |

|

06652 |

0.65 |

0.65 |

7.4 |

6.8 |

1600 |

650 |

0.65 |

1.19 |

18.8/17.3 |

0.70/0.82 |

14400 |

1190 |

28.96 |

|

06802 blue/white |

0.8 |

0.8 |

6.6 |

6.5 |

1600 |

650 |

0.85 |

1.45 |

16.8/16.5 |

0.72/0.73 |

11600 |

725 |

22.65 |

|

06702 blue/white |

0.7 |

0.7 |

7 |

7 |

1600 |

650 |

0.77 |

1.3 |

17.8/17.8 |

0.72/0.72 |

11000 |

690 |

26.01 |

|

07802 |

0.8 |

0.8 |

7.8 |

7 |

1600 |

650 |

1.1 |

1.45 |

20.3/18 |

0.32/0.54 |

5920 |

370 |

16.54 |

|

09502 |

0.5 |

0.5 |

9.7 |

10.3 |

1600 |

650 |

0.5 |

0.9 |

25/26.2 |

0.53/0.47 |

10100 |

634 |

24.97 |

|

012502 |

0.5 |

0.5 |

13.5 |

8.5 |

1600 |

650 |

0.63 |

0.95 |

34.3/21.6 |

0.24/0.65 |

6500 |

6280 |

18.68 |

|

09452 |

0.45 |

0.45 |

10 |

8.6 |

1600 |

650 |

0.45 |

0.88 |

25.4/21.8 |

0.55/0.71 |

15570 |

970 |

33.71 |

|

08603 |

0.5 |

0.6 |

9.4 |

9 |

1600 |

650 |

0.6 |

0.95 |

23.8/23.1 |

0.56/0.51 |

9000 |

560 |

24.38 |

|

08502 |

0.5 |

0.5 |

9.5 |

8.6 |

1600 |

650 |

0.89 |

0.47 |

24.13/21.8 |

0.50/0.65 |

10140 |

634 |

29.93 |

|

06803 |

0.7 |

0.8 |

7 |

5.5 |

1600 |

650 |

0.75 |

1.53 |

17.8/14 |

0.72/1.0 |

16000 |

1000 |

28.56 |

|

Alkali resistance |

1 |

1 |

4.5 |

5.5 |

1600 |

650 |

0.65 |

1.63 |

17/14 |

0.35/0.60 |

5920 |

370 |

14.85 |

|

09603 |

0.5 |

0.6 |

10.5 |

9.2 |

1600 |

650 |

0.65 |

1.05 |

26.67/23.4 |

0.45/0.48 |

8300 |

518 |

44.87 |

|

07803 |

0.8 |

0.8 |

8 |

8 |

1600 |

650 |

1.15 |

1.66 |

20.3/20.3 |

0.45/0.45 |

6400 |

400 |

16.26 |

|

07903 |

0.8 |

0.9 |

7.6 |

6.5 |

1600 |

650 |

1.25 |

1.76 |

19.3/16.5 |

0.51/0.63 |

9184 |

574 |

12.96 |

KEYLIFE Mesh Belt For Mining

Industry: Mining

Application: Washing, Dewatering, Filtering+ Separating

KEYLIFE mesh belts support washing and dewatering of raw materials, salts, and minerals in belt filter systems. Applications range from sodium chloride, potassium chloride, and kieserite.

Because the montane processes differ in accordance with local conditions, KEYLIFE always adapt the selection of belts accordingly. The result: belts that always perfectly meet requirements.

Technical superiority:

- Custom-built dewatering products;

- Stock goods;

- Own research & development.