Spiral Dryer Fabric for All Paper Machines

Boost your production efficiency with our advanced dryer fabric technology. Built to last, our dryer fabrics provide excellent drying capabilities, extending the lifespan of your machine while delivering high-quality paper products.

Description

Reviews

Description

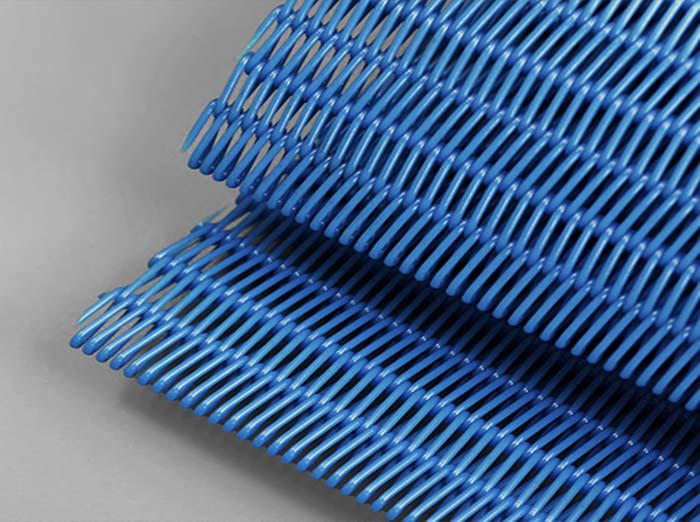

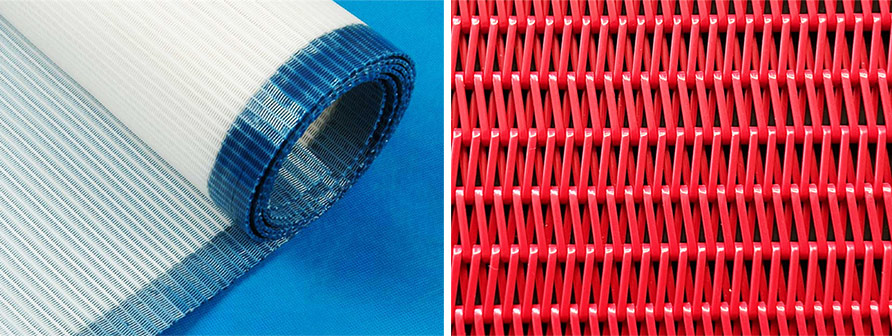

Spiral dryer fabric or screen is an endless construction comprising a plurality of spiral loops of monofilament yarns. The spiral loops are linked by a pin yarn inserted in the adjacent holes.

The specially designed spiral structure allows for rapid drainage, and superb distortion resistance and eliminates the need for conventional seams compared with the woven polyester dryer fabric.

The spiral dryer fabric is a specially engineered paper machine clothing for the drying sector in the paper mill, also widely deployed in many other industries like food drying, nonwoven conveying, printed textile drying, etc.

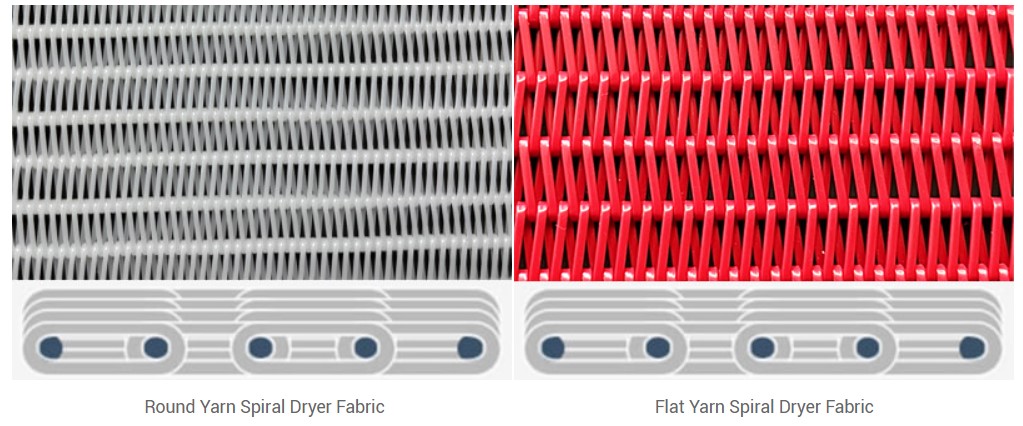

According to your requirements, polyester spiral dryer fabric can be fabricated with round yarns or flat yarns. In contrast, the flat yarn spiral dryer is recommended to be used in high-speed paper drying machines owing to its smoother surface, better wear resistance, later contacting area, and most of all, improved paper drying performance.

Spiral dryer fabrics is made of hydrolysis and abrasion-resistant PET and has a medium to high permeability(150 to 900 CFM).

The seam of the fabric consists of spirals of the same quality and strength as the bulk of the fabric.

Spiral dryer fabrics have high diagonal stability and relatively uniform distribution of tension and air permeability and are suitable for drying locations where joint damage usually occurs.

Feature

● Spiral dryer fabric is available in a broad air permeability range.

● Spiral dryer fabrics are easy to fit and install, simple to clean and remain stable even after long-running times of operation.

● Max air permeability and high wear resistance.

● Excellent dimensional stability.

● Excellent abrasion resistance and durability.

● Spiral dryer fabrics have no seam markings or premature wear.

● Spiral dryer fabrics can add ventilation holes to improve drying/reduce energy costs.

● Spiral dryer fabrics have greater permeability and drying efficiency.

● Spiral dryer fabrics use high-temperature hydrolysis-resistant yarns.

● Spiral dryer fabrics have a good tensile strength.

● Spiral dryer fabrics have a flexible and strong edge reinforcement.

Application

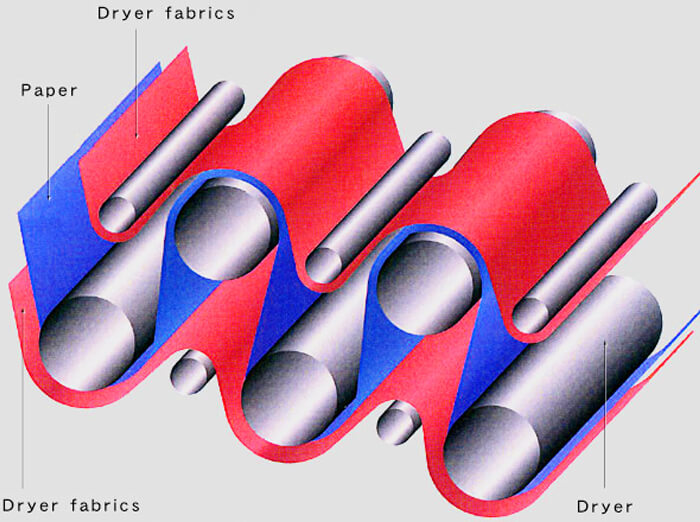

In the dryer section of the paper machine, the paper sheet travels around large-diameter heated cylinders, remaining water is removed by evaporation. Spiral dryer fabrics are widely used in various industries as papermaking dryer fabrics, filter mesh belts, or dryer conveyor belts.

|

Spiral dryer fabric for paper making |

Spiral dryer belt for tea drying |

Spiral dryer fabrics are widely used in many other industries such as food drying, non-woven conveying, printing textile drying, and so on.

Spiral dryer fabrics is mainly used for multi-cylinder fourdrinier paper machines and multi-cylinder cylinder machines, suitable for all kinds of board paper, corrugated paper, kraft paper, bag paper, tube paper, linoleum base paper, train ticket paper, thick board paper, pulp board paper and heavy-duty writing paper and wrapping paper.

Since the advent of the vacuum washer, spiral dryer fabrics has become a special filter fabric.

Spiral dryer fabrics are also used in rotary screen printing machines in the printing and dyeing industry, coal washing machines in the coal washing industry, oven conveyor belts in the food processing industry, etc., to obtain the best performance.

KEYLIFE Spiral Dryer Fabric- Style 1833

Spiral dryer fabric 1833 provides many benefits for paper machine operations. Composed of 100% polyester monofilament, the fabric provides excellent abrasion resistance and excellent stability even at very high permeabilities. On machines with no pocket ventilation system or an insufficient system, the air pumping capacity of 1833 high permeability design increases air flow into the pocket to help mass transfer.

The results are improved drying and reduced energy costs, or speed increases on dryer limited machines. The spiral fabric becomes endless after joined, thus no issues for seam strength or wear or marking. The coil construction provides the ability to remove damaged sections of the fabric. Spiral fabric 1833 is the need of wide- permeability range, stable, abrasion resistant application.

Technical superiority:

- Improved drying & reduced energy costs;

- Speed increase on dryer limited machines;

- Excellent wear resistance;

- Excellent dimensional stability;

- No seam mark

- Ability to remove damaged sections.