SSB Triple Layer Forming Fabric For Cultural Paper Machines

Durability Meets Performance in Our Paper Machine Forming Fabric: Our paper machine forming fabric offers unmatched durability and superior performance, helping you produce high-quality paper with consistency and reliability.

Description

Reviews

Description

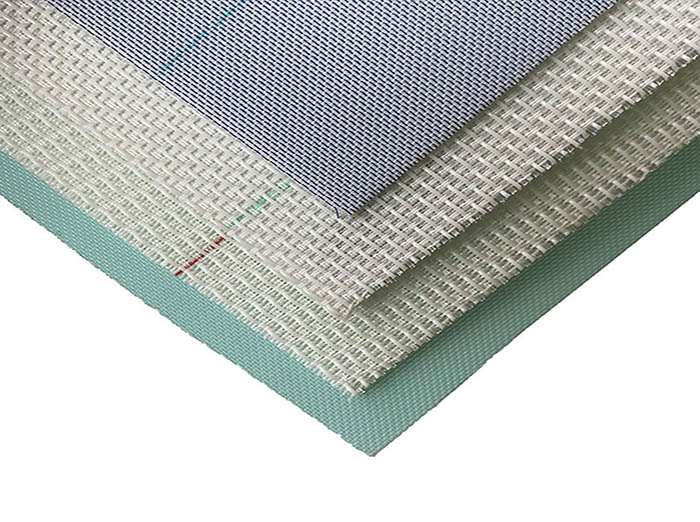

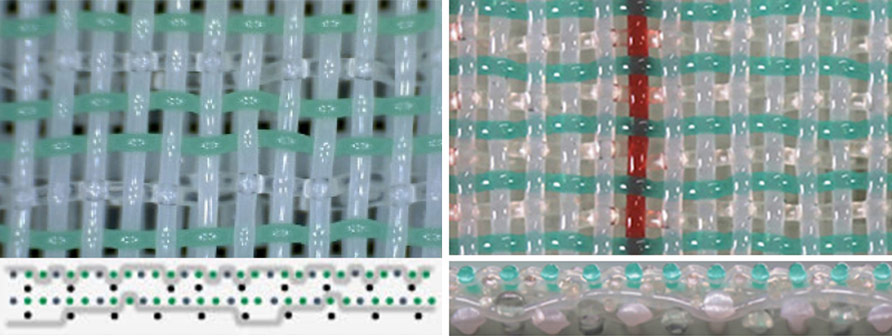

SSB triple-layer forming fabrics have two independent single-layer fabrics bound together by separated yarns.

On the forming side, the yarns have a small diameter to increase the support index. On the wear side, cross-direction yarns have a large diameter to improve the fabric life.

The wear side is made with a coarse mesh to improve stability and wear resistance. The paper side is made with very fine yarns on the surface to optimize the sheet forming performance.

This modified design delivers enhanced stability in the cross-machine direction thanks to its three-ply weft structure. Furthermore, improved drainage is guaranteed because of its increased three-dimensional space.

SSB triple Layer Forming Fabric

Feature

● Better drainage performance

● Better stability and abrasion resistance.

● Longer service life

Application

SSB triple layer forming fabric is the best for those who wants to retain as much fiber and faster drainage as possible. The increase with the count of the yarn ensures better support and retention while at the same time reduces the wire marks.

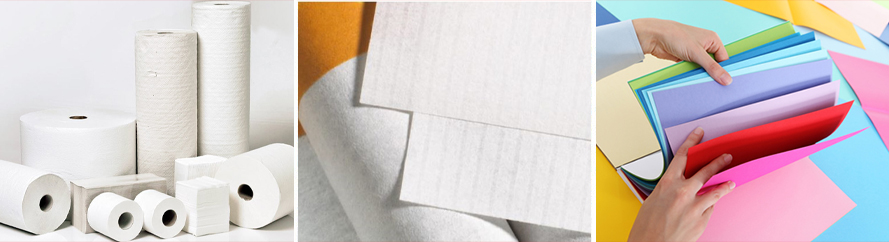

SSB triple-layer forming fabric is suitable for producing quality printing paper, tissue paper and cigarette paper, etc. Due to its excellent stability and resistant, it is ideal for high-speed paper machine.

KEYLIFE SSB Forming Fabric- Style FORM TF

FROM TF is designed for fine grades (xerox, printing & writing, coating base…) whatever the speed of the paper machine. It provides a high level of fiber support, better formation and high fabric stability for good CD profiles, by the combination of two technologies – high-shaft weaving and a 3:2 warp ratio.

Due to the unique warp concept of style FORM TF, an even finer paper side can be combined with an extremely stable machine side. This way, a much higher fiber support is achieved, leading to better mechanical retention and more uniform sheet formation.

Technical superiority:

- High sheet support – Improved retention, smoothness and low marking

- Dewatering capacity – Lower HB consistencies and improved formation

- Fine fabric surface – Easy sheet release and low fiber carry back

- Enhanced stability – Reduced CD profile variation

- Robust wear side – High abrasion resistance and longer life potential