Woven Dryer Fabric Resistant to Edge Degradation

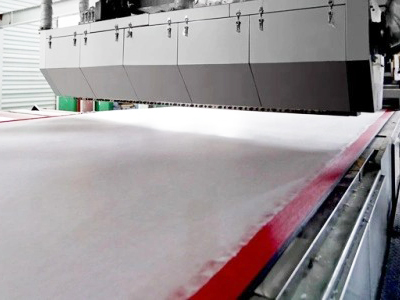

Reduce energy costs and improve the drying process with our high-quality dryer fabrics. Designed to maintain stability and efficiency even in extreme temperatures, our fabrics ensure optimal moisture removal and smooth operations for your paper machine.

Description

Reviews

Description

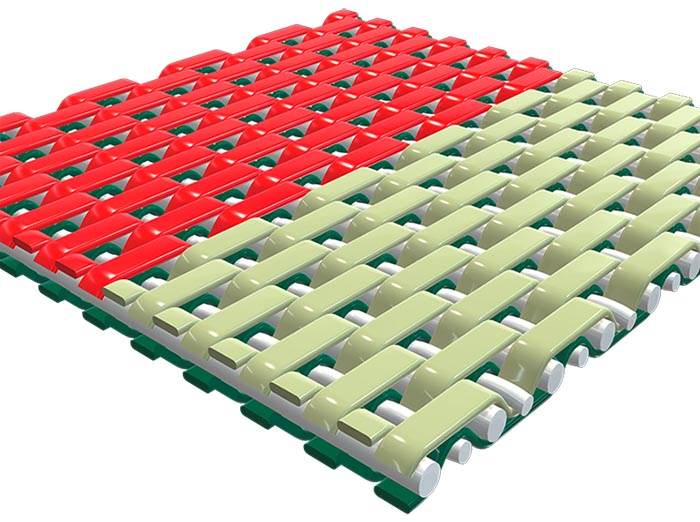

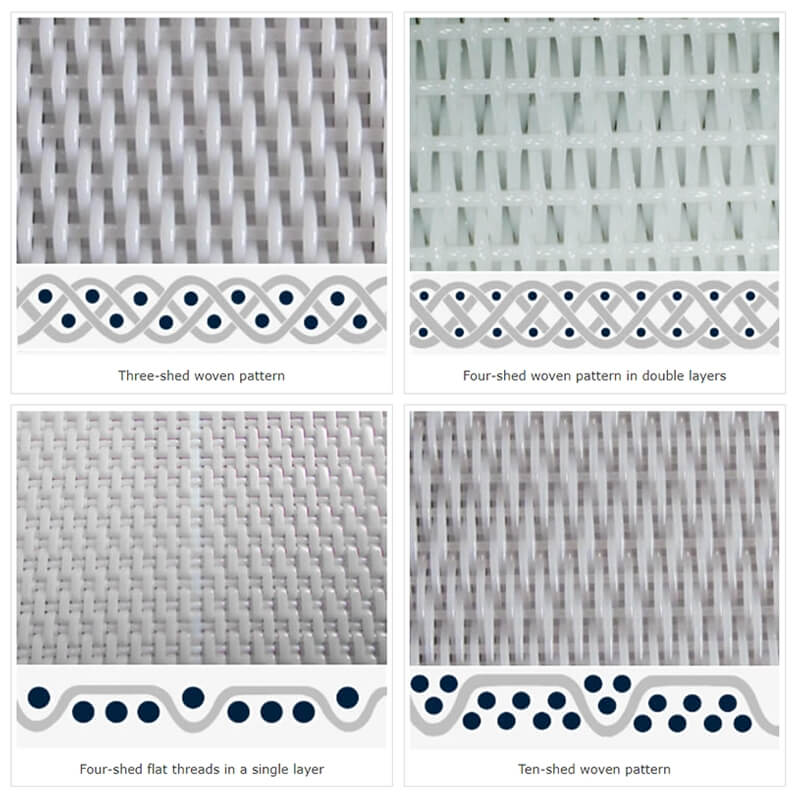

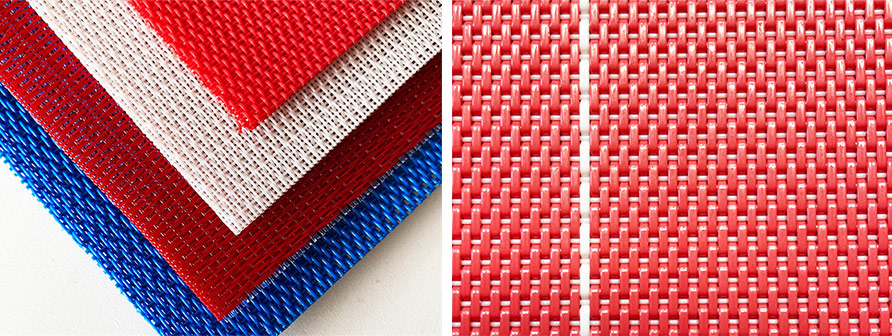

Woven polyester dryer fabric can be fabricated in single, double or two and a half layers to achieve different air permeability. It is also available in three-shed, four-shed or other various woven patterns based upon request.

Woven dryer fabric influences the drying process by openness and contact area with the paper sheet. Different yarn structures and shapes are used to control air permeability (CFM) and influence properties such as contact area, wear resistance, stability and cleanliness.

Dryer fabrics are woven with round or flat monofilaments for drying requirements of different paper grades, and different machine speeds. Flat wire dryer fabric is mainly used in the fore heating box of the drying zone, and also can be used for all paper grades.

Normally, the three-shed fabric is perfect for drying papers less than 70g and a four-shed one is ideal for those papers of weight larger than 70g. In addition, woven polyester dryer fabric can be made to custom orders.

Feature

● PPS (Phenylene sulfide) materials are available as a choice to reinforce the edge to operate in severe conditions.

● We use different yarn structures and shapes to control air permeability and other properties such as contact area, wear resistance, stability and cleanliness.

● Rectangular or flat monofilament yarns are used as machine yarns and cross-directional yarns to improve runnability, sheet handling and wear potential on high-speed machines.

● We offer special materials for our dryer fabrics to have the characteristics of high-temperature resistance, abrasion resistance and aging resistance, etc.

Application

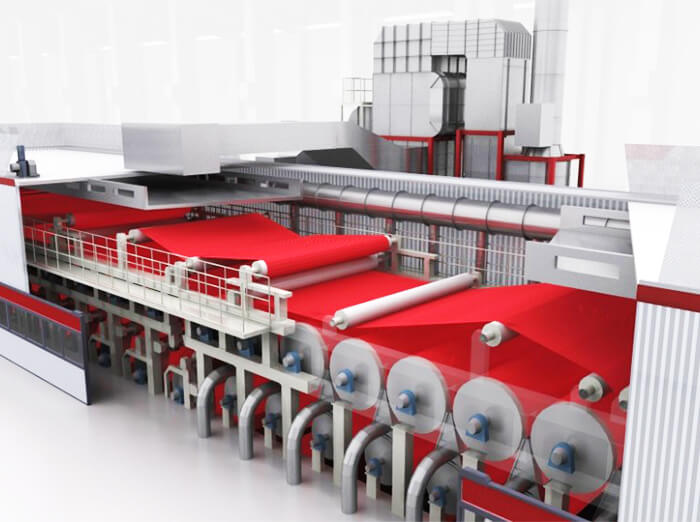

The fabric is widely used in papermaking, mining, food, pharmaceutical, printing and dying, and rubber industry. It can be also used as a conveyor belt and the laminating machine belt.

For paper machines, the woven dryer fabrics are suitable for drying packing paper, cultural paper, board paper and pulp board.

|

Dryer fabrics for paper making |

Dryer belt for non-woven fabric |

KEYLIFE Dryer Fabric- RE Design

KEYLIFE RE design of dryer fabric has unique properties that set it apart from other high performance dryer fabrics. The fabric provides edge protection where most heat, hydrolytic and oil degradation occurs. Plus, the unique construction provides the superior contact area, mechanical properties of the fabric body for maximum smooth surface, strength and abrasion resistance, as Keylife’s standard dryer fabrics offer.

Technical superiority:

- Resistant to edge degradation from heat, hydrolysis and oil;

- Resistant to abrasion and wads;

- Reduced air carrying for better sheet control;

- High contact area for improved drying/energy savings.